Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

Online Condition Monitoring (CM) is the continuous collection of data of a machine or production process.

Online CM systems either send out warnings based on predetermined alert thresholds or by detecting abnormal behaviour.

They will indicate early signs of machinery problems, however they do not provide precise information about the problem.

The majority of these systems provide fairly intuitive dashboards to present the information collected to the end user, however:

That's where we come in.

As qualified and experienced CM engineers we can analyse the data you have to identify the root cause of the problem.

This may be possible by remote analysis of on-line data onshore or may require a site visit for in-depth data analysis.

Identification of the actual fault that has resulted in the online warning will significantly speed-up fault rectification and minimise machine down-time.

We can also help optimise your online monitoring program to ensure alarms are relevant, timely and give the maximum amount of fault information.

With the dawn of the Industrial Internet of Things (IIoT), combined with cloud-based computing, the way that data is collected and stored has now evolved.

Many Condition Monitoring system providers have adopted the Software as a Service (SaaS) model whereby a specialized provider maintains the system on your behalf. This can be beneficial due to the large IT resources and expertise required to maintain such a system.

Online monitoring systems are becoming more commonplace as costs decrease, and can be fantastic tools for monitoring machinery health, but they are not the only solution out there and they do require considerable expertise to get the most out of them.

Highly sensitive to variation

Dynamic bands & static thresholds

Less exposure to hazardous environments

Scalable

Cost

Short term events & Transients often overlooked

Miss out Visual and Audible clues from physical inspection

Lack of clarity of detected problems

Online CM systems can utilise relevant parameters, such as temperature, pressure and vibration to build a complete picture of each machine monitored. The software will, often in real-time, compare the various sensors data to that of known expected values for that machine. By looking at the difference between real-time data and normal, predicted behaviour, the software can detect events and abnormal behaviour, send out notifications and ultimately provide early warning detection of potential faults.

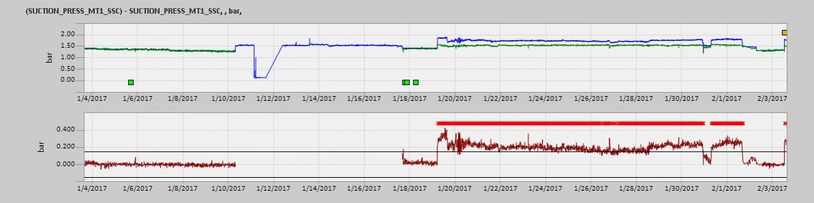

A trend graph highlighting a period of high suction pressure.

The life of a machine is dependent on the condition of its constituent parts so it is vital any faults that develop are found early on. This gives operators the time necessary to plan for any part changes that may be required.

Online CM systems provide flexibility in how often analysis is conducted, allowing the analyst to modify the time interval between checks as faults start to develop so they can more closely monitor the defects progression.

As qualified and experienced CM engineers we can analyse the data you have to identify the root cause of the problem.

We can also help optimise your online monitoring program to ensure alarms are relevant, timely and give the maximum amount of fault information.

For a more complete package we can combine remote analysis with traditional offline data collection and oil analysis.

Please contact us to find out more or to discuss opportunities.

Copyright © 2020 Machine Diagnostics Ltd - All Rights Reserved.

This website uses cookies. By continuing to use this site, you accept our use of cookies.