Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

A Water Injection Pump Performance Test shows a 15% drop in efficiency.

The benefits of monitoring oil filters.

Logging Differential Pressures on oil system filters can allow filters to be changed out at convenient shut-downs and also keeps a record of when the filter was last changed (this can be just as important on duplex filter).

In this example, prior to logging in this manner, the seal oil filter cartridge had never been changed-out and collapsed, contaminating the whole seal oil system.

A shutdown resulted because of damage to the mechanical seals caused by the cartridge.

Rising trend of a Water Injection Pumps thrust bearing temperature.

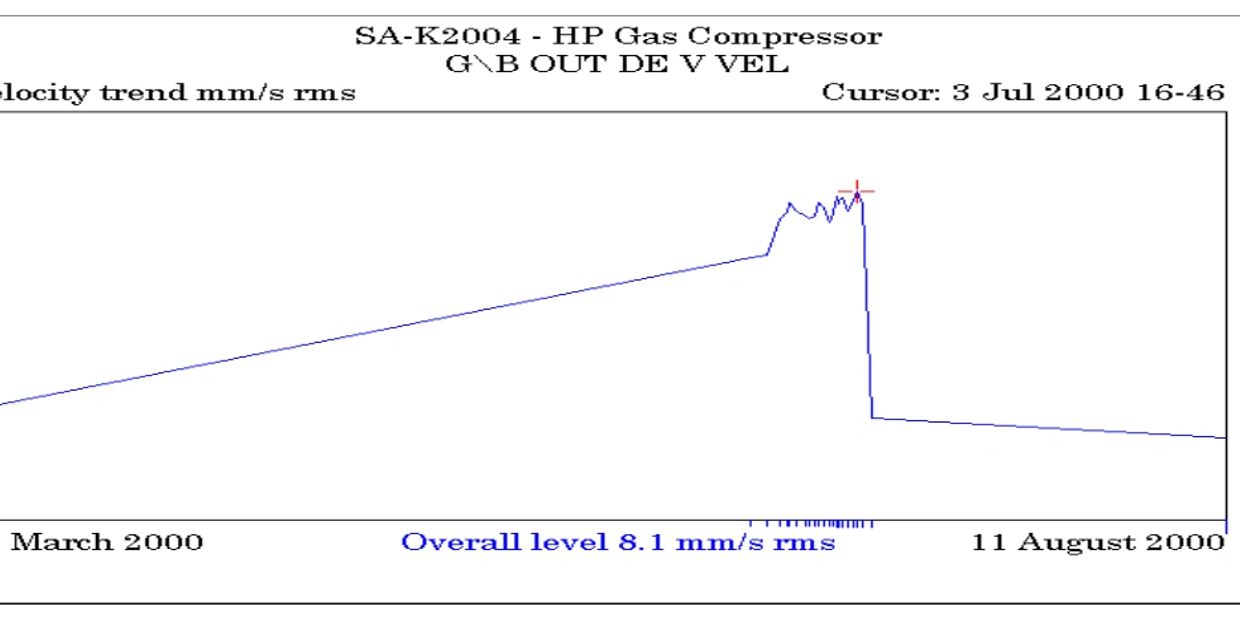

Gearbox Output Shaft DE Vertical Trends.

Overall level shows a significant increase following maintenance.

Investigation show instrumentation software upgrade introduced a significant calibration error.

Gas Turbine being monitored for power loss.

Copyright © 2020 Machine Diagnostics Ltd - All Rights Reserved.

This website uses cookies. By continuing to use this site, you accept our use of cookies.