Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

Cost benefit of Vibration Analysis and Condition Monitoring

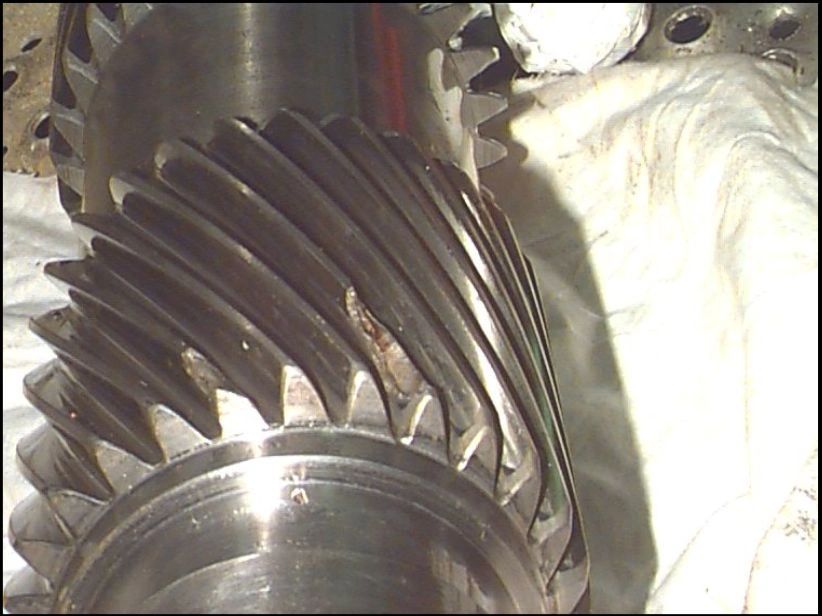

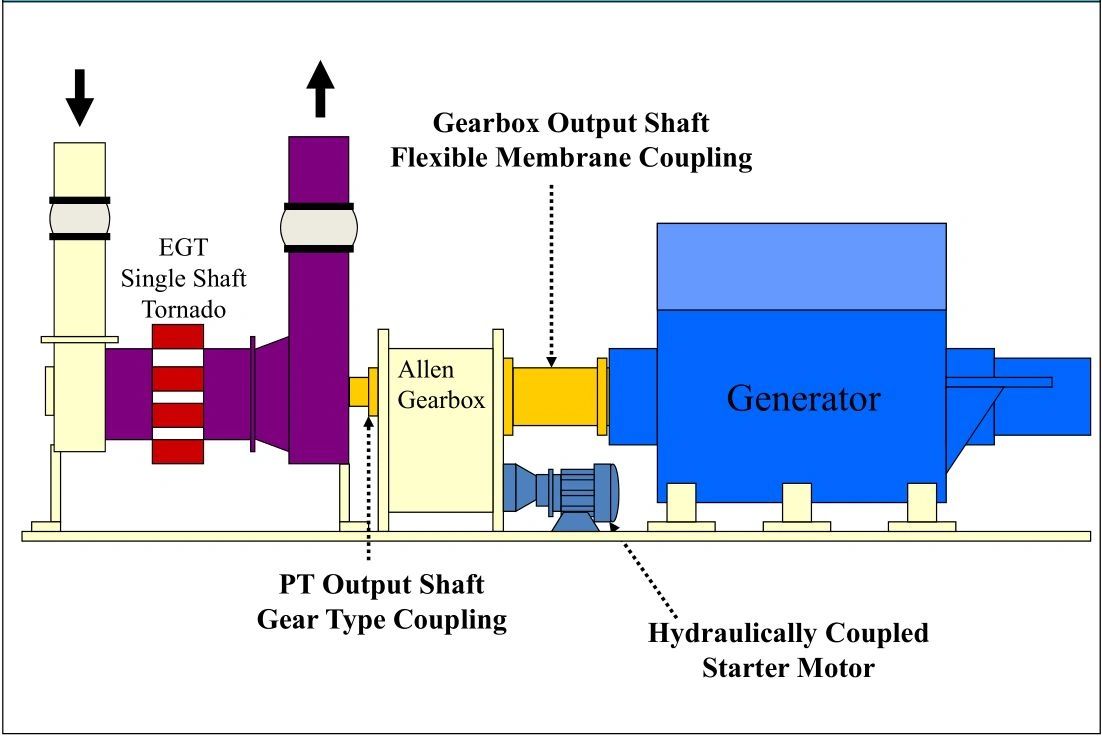

Vibration Analysis shows a gear-meshing problem.

New pinion shaft required but catastrophic failure avoided.

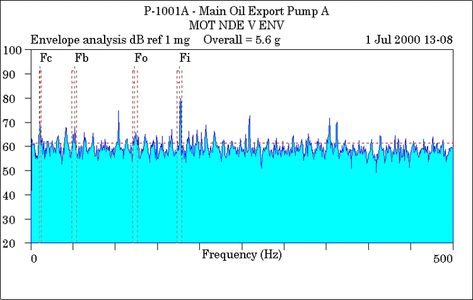

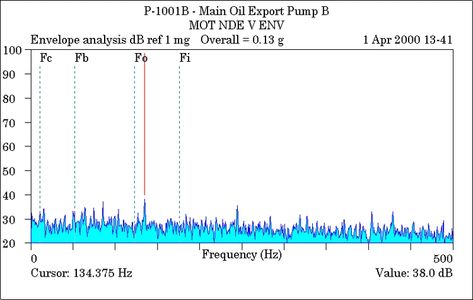

Comparable readings from two identical set-ups.

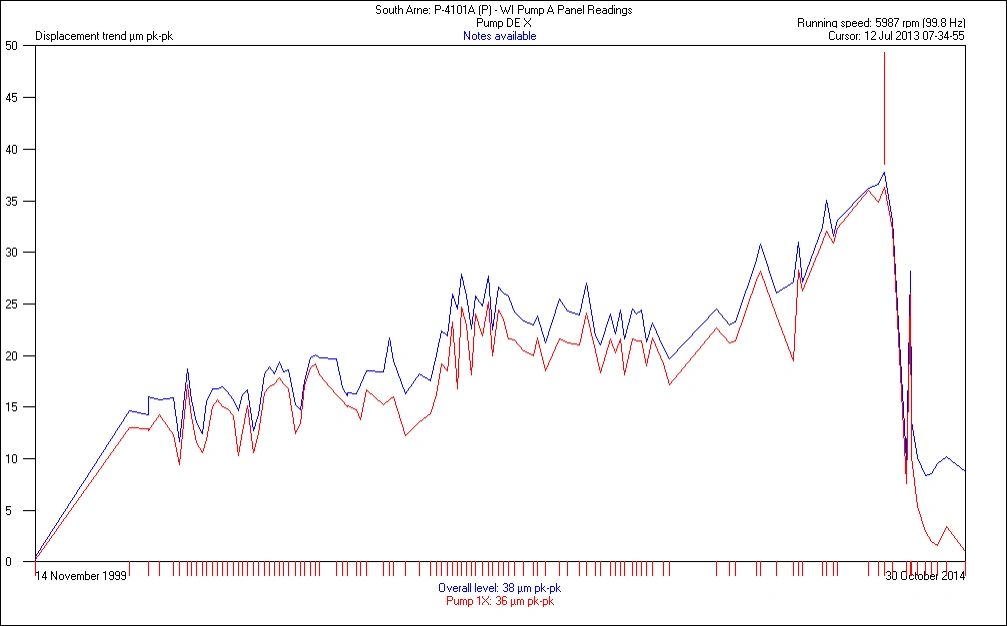

Identifying and correcting excessive bearing clearance.

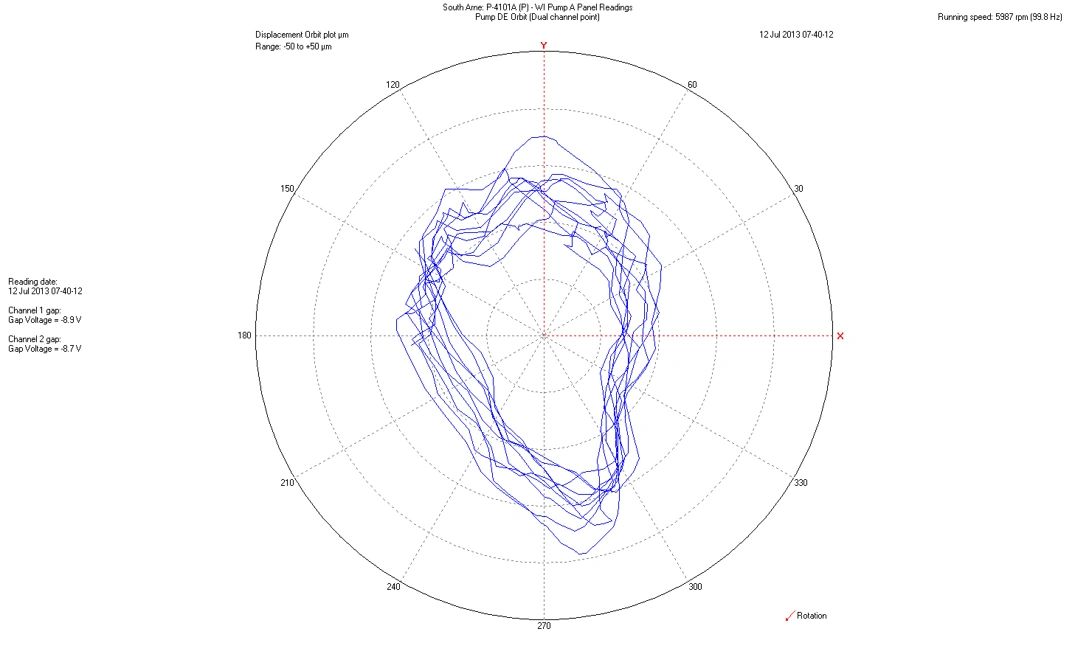

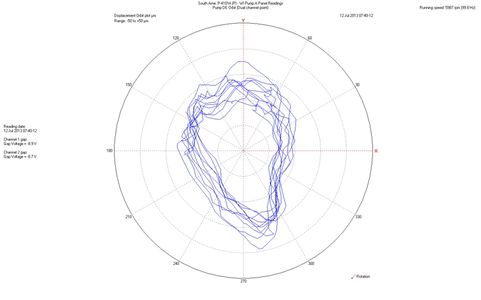

Slow increase in 1x vibration together with instability indicated excessive bearing clearance.

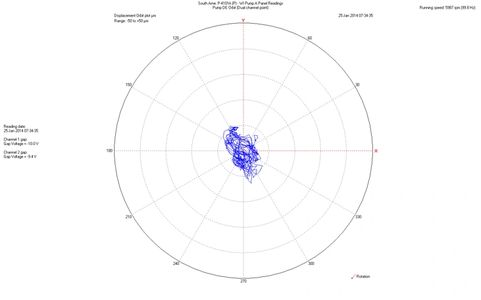

The pump DE bearing was replaced and vibration reduced from 40 μm to 5 μm p-p.

Pump DE Shaft Orbit before bearing change.

Pump DE Shaft Orbit after bearing change.

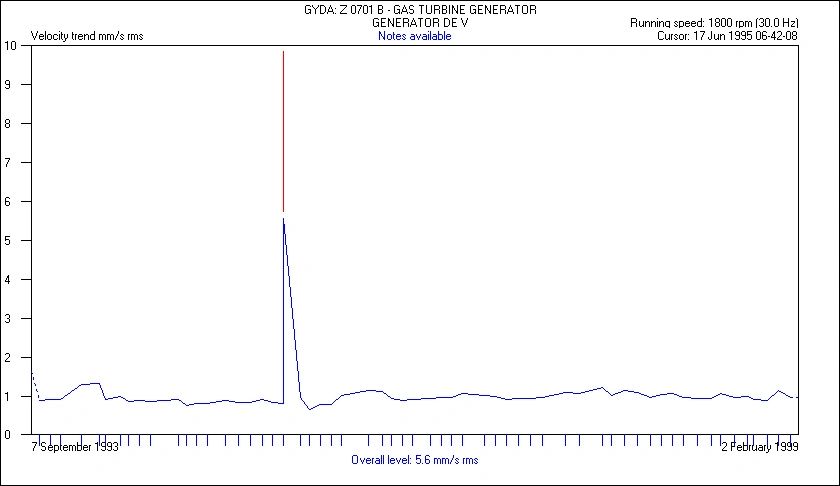

Gas Turbine electrical issue highlighted by Vibration Analysis

Copyright © 2020 Machine Diagnostics Ltd - All Rights Reserved.

This website uses cookies. By continuing to use this site, you accept our use of cookies.